The watch dial, a key component of a luxury watch, goes far beyond its functional role. It is a canvas where the creativity and expertise of watchmakers come to life. Among the many steps in its production, brushing, also known as dacron, stands out as an essential technique, adding texture, depth, and brilliance. This process contributes to the uniqueness and refinement of each watch.

Brushing: A Precision Technique Serving Aesthetic Watchmaking

Dial brushing, also referred to as dacron, involves applying controlled friction to the surface of the dial to create a matte, satin, or striped finish. This method enhances details, reduces the shine of smooth surfaces, and adds a remarkable visual and tactile texture.

Types of Brushing and Their Effects

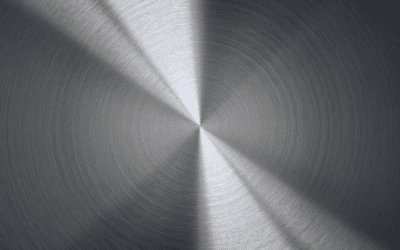

Circular Brushing:

Creates spiral patterns, ideal for steel dials, offering a subtle diffusion of light.

Linear Brushing:

Produces parallel lines, adding a sophisticated sense of depth.

Perpendicular Brushing:

Provides a bold and structured finish for a more assertive design.

The choice of brushing type, or dacron, depends on the desired aesthetic and the elements to highlight, such as logos, indices, or hands.

Challenges of Dial Brushing in Watchmaking

Brushing, or dacron, is a delicate step that demands extreme precision and advanced technical skills. Key challenges include:

- Uniformity of the finish: Any visible irregularity is unacceptable in luxury watchmaking.

- Tool selection: Abrasives must be carefully chosen to avoid damaging the dial’s surface.

- Mastery of technique: A single misstep can compromise the final aesthetic.

These demands drive watchmakers to seek increasingly advanced tools and technologies.

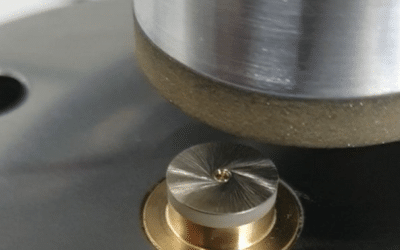

SwissKH: Innovating for Precision Brushing

SwissKH Sàrl, a recognized leader in the watchmaking industry, has developed a machine dedicated to dial brushing. Designed to meet the needs of watchmakers, this machine combines precision and consistency through advanced technologies, including:

- Numerical control for precise movement management.

- Automated control systems to ensure uniform quality.

- Customization of finishes to meet the specific demands of luxury brands.

This innovation not only enhances efficiency but also achieves unparalleled quality standards.

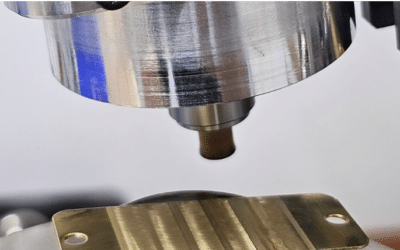

The Future of Brushing: Between Craftsmanship and Technology

The combination of traditional craftsmanship and modern technologies is redefining dial brushing, or dacron. Through partial automation, watchmakers can:

- Maintain the spirit of manual precision while increasing productivity.

- Meet the growing demands of the industry without compromising quality.

Machines like those developed by SwissKH embody this transition, offering solutions that respect the art of watchmaking while integrating cutting-edge tools.

Conclusion: Brushing, or Dacron, An Art in Service of Watchmaking Excellence

Dial brushing, or dacron, is far more than a simple step in the production of a watch. It reflects the expertise and pursuit of excellence of watchmakers. Technological innovations, such as SwissKH’s machine, elevate this technique to unprecedented levels, ensuring flawless finishes while honoring the traditions of watchmaking.

In a constantly evolving sector, brushing remains a discipline that merges tradition and innovation. SwissKH is proud to shape the future of this essential practice, offering solutions tailored to the needs of tomorrow’s watchmakers.