The creation of machine fairings is a complex process

that requires a combination of engineering, design and manufacturing skills. Fairings are enclosures that protect a machine’s internal components and users, and can also improve the machine’s appearance and ergonomics.

Here are the general steps for creating a machine fairing:

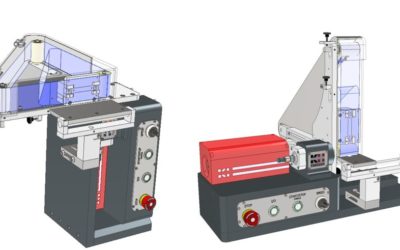

1. Design:

The first step is to design the fairing according to the machine’s requirements and the user’s needs. This may involve using CAD software to create a 3D model of the fairing. Handling requirements for after-sales service are also taken into account. Hatches for modifying, cleaning or replacing parts are important. A well thought-out machine fairing saves time and money.

2. Material selection

The choice of fairing materials depends on a number of factors, including strength, durability, appearance and cost. Materials commonly used for machine fairings include metals, plastics and composites.

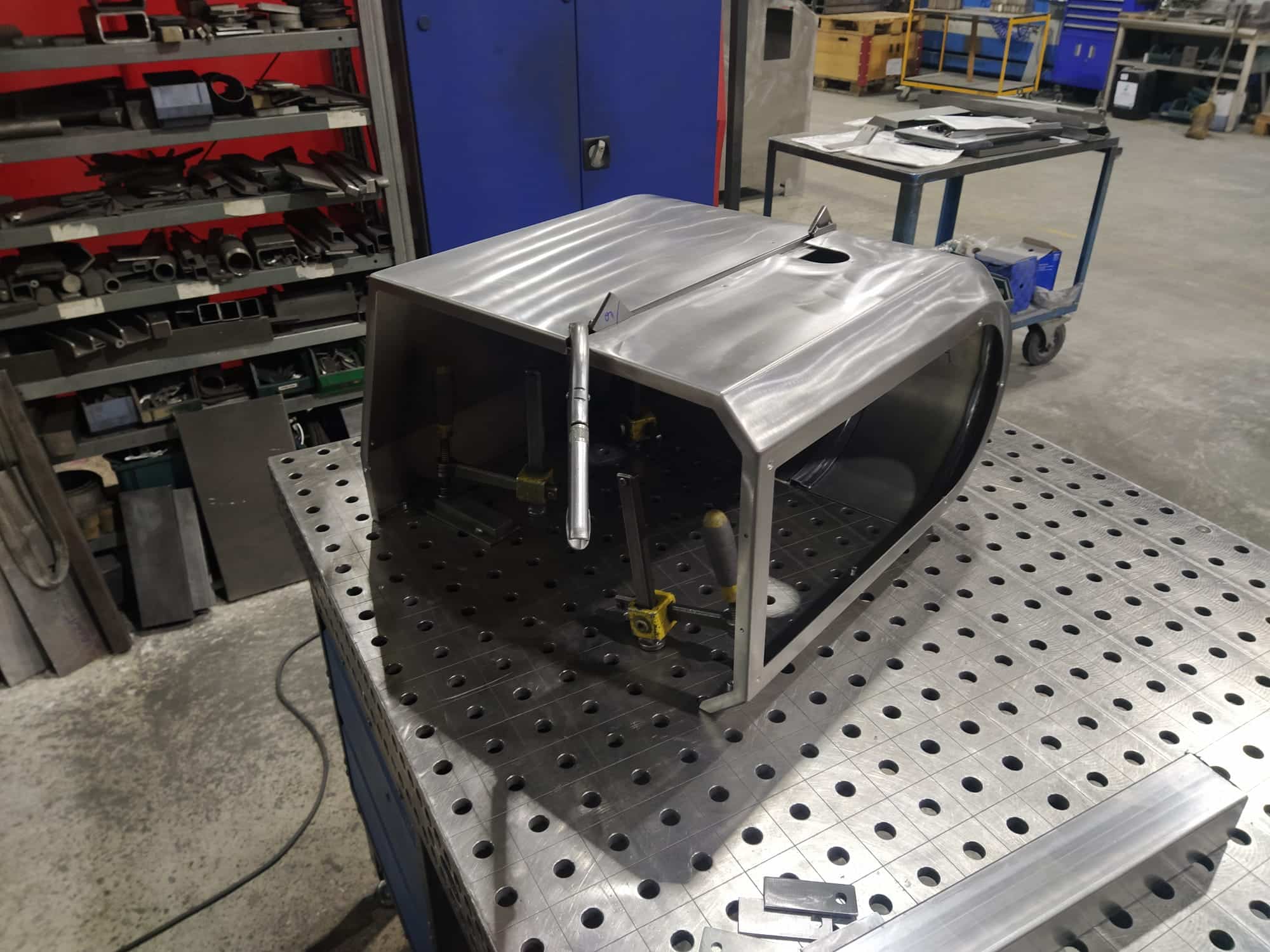

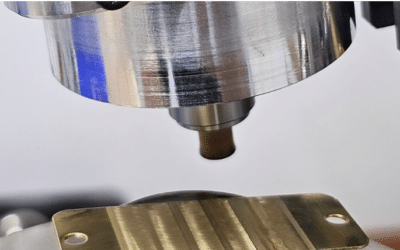

3. Manufacturing

Once the design and selection of materials have been completed, manufacture of the fairing can begin. Common manufacturing methods include machining, molding, welding, laser cutting and 3D printing.

4. Finishing

The penultimate stage involves applying finishes to the fairing, such as painting, polishing or anodizing to enhance its appearance and durability. Additional dimensions, laser engraving or other decorative elements can also be applied using stickers.

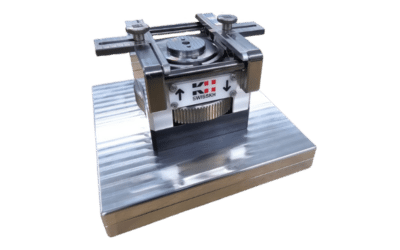

5. Assembly

The final step is to assemble the final fairing. This requires a great deal of know-how, in terms of cable management, grounding and careful assembly and fitting.

It’s important to note that every machine fairing creation project is unique, and may require additional or different steps depending on specific project requirements.

SwissKH’s experience can guide you in the right direction. Please contact us for more information.