In the field of machine tools, choosing the right Computer Numerical Control (CNC) system is crucial for ensuring precision, performance, and connectivity in industrial equipment. Among the available options, Fanuc, Siemens, NUM, and Beckhoff stand out for their features. However, Beckhoff emerges as a must-have choice for Industry 4.0, thanks to its advanced capabilities in customization, ergonomics, and communication.

CNC Systems: A Comparative Overview

Each CNC system offers specific features tailored to different industrial needs. Here’s a comparison of the most popular solutions:

Fanuc: Robustness and Simplicity

- Known for its ease of use and durability.

- Ideal for high-speed applications, such as machining and industrial robotics.

- Offers excellent precision and speed, particularly suited for intensive production environments.

Siemens: Versatility and High-End Performance

- The Sinumerik range from Siemens is geared toward complex applications, including 5-axis machining and advanced robotics.

- Strong connectivity with solutions designed for Industry 4.0.

- A scalable and robust CNC for demanding environments.

NUM: A Niche Choice for Watchmaking and Precision

- Favored in specialized sectors such as the watchmaking industry and custom manufacturing.

- Its flexibility and adaptability make it an ideal choice for specialized machinery.

Beckhoff: Flexibility and Customization

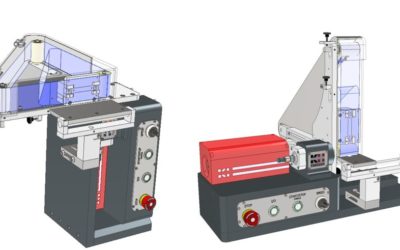

- With its PC-based Control technology, Beckhoff offers an ultra-flexible CNC system.

- Excels in programming, ergonomics, and communication.

- Perfect for Industry 4.0, where customization and connectivity are key.

Beckhoff: A Solution for Industry 4.0

Beckhoff redefines the standards of traditional CNC systems with its advanced capabilities. Here’s why it stands out:

HTML and Custom HMI Interfaces

- Enables the creation of custom Human Machine Interfaces (HMI) using HTML technology.

- Benefits include:

- Ergonomics and intuitiveness: Simplified interfaces tailored to operators.

- Real-time data visualization: Quick access to critical parameters.

- Simplified diagnostics: Facilitates monitoring and maintenance.

Compatibility with Modern Communication Protocols

- Beckhoff supports advanced protocols such as OPC UA, MQTT, and EtherCAT, essential for industrial interconnectivity.

- These protocols enable:

- Bidirectional communication between machines and systems.

- Seamless integration into complex ecosystems.

- Real-time data sharing for smart automation.

Industry 4.0: Beckhoff’s Strategic Advantages

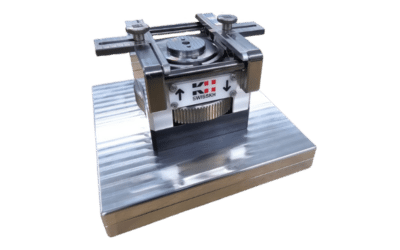

Flexibility and Adaptability

- Beckhoff systems allow total customization of controls and interfaces.

- Perfectly suited for companies focused on industrial innovation.

Continuous Performance Improvement

- Real-time data analysis optimizes machine performance.

- Beckhoff enables smart production, reducing errors and increasing productivity.

A Pillar of Digital Transformation

- Beckhoff helps companies integrate their machines into fully interconnected processes, becoming a key player in digital transformation.

Conclusion: Beckhoff, a Strategic Choice for the Future

For companies embracing Industry 4.0, Beckhoff offers a CNC solution that combines flexibility, ergonomics, and advanced connectivity. With its ability to customize HMI interfaces and integrate into smart environments, Beckhoff positions companies at the forefront of industrial automation.

Ready to modernize your CNC systems? Discover how SwissKH can support you with tailored Beckhoff solutions designed to address your industrial challenges.